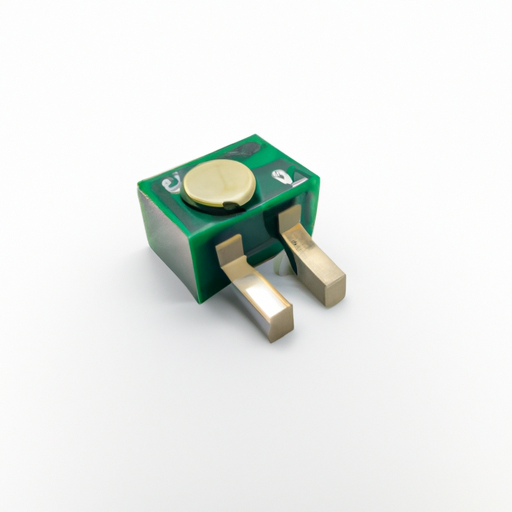

Core Functional Technologies of Trimmer Potentiometers1. Adjustable Resistance: Trimmer potentiometers, such as the CFR-50JB-52-1K3, offer a variable resistance that can be manually adjusted. This feature is essential for calibrating circuits, allowing engineers to set precise voltage levels or current flows, which is critical in applications requiring fine-tuning.

2. Compact Design: The CFR-50JB-52-1K3 is engineered with a compact footprint, making it ideal for space-constrained applications. Its small size allows for seamless integration into various electronic devices without occupying excessive space, which is particularly beneficial in portable electronics. 3. Durability and Reliability: Built to endure repeated adjustments, trimmer potentiometers in the CFR series are known for their robust construction. This durability ensures long-term reliability, even in demanding environmental conditions, making them suitable for both consumer and industrial applications.

4. Temperature Stability: Many trimmer potentiometers, including the CFR-50JB-52-1K3, maintain their resistance values across a wide temperature range. This characteristic is crucial for applications that operate in varying thermal environments, ensuring consistent performance.

5. Low Noise Operation: Designed to minimize electrical noise, trimmer potentiometers are essential in sensitive applications such as audio equipment and precision measurement devices. The low noise operation helps maintain signal integrity, which is vital for high-quality performance.

Application Development Cases1. Audio Equipment Calibration: In high-fidelity audio amplifiers, trimmer potentiometers like the CFR-50JB-52-1K3 are used to adjust gain levels. This fine-tuning capability ensures optimal sound quality and prevents distortion, enhancing the listening experience.

2. Sensor Calibration: Trimmer potentiometers are instrumental in calibrating sensor outputs, such as those from temperature or pressure sensors. By adjusting the resistance, engineers can align the sensor output with expected values, thereby improving measurement accuracy in various systems.

3. Power Supply Regulation: In power supply circuits, trimmer potentiometers are frequently employed to set output voltages. For instance, in a DC-DC converter, the CFR-50JB-52-1K3 can be adjusted to achieve the desired output voltage, providing flexibility in design and application.

4. Feedback Control Systems: In robotics and automation, trimmer potentiometers can be utilized to set reference levels for feedback loops. This precision is crucial for maintaining performance in control systems, ensuring that devices operate within desired parameters.

5. Consumer Electronics: Trimmer potentiometers are commonly found in consumer devices like televisions and radios, where they are used to adjust tuning and volume levels. The CFR-50JB-52-1K3 can be integrated into these devices, allowing users to customize their experience easily.

6. Test Equipment: In laboratory environments, trimmer potentiometers are often used in test equipment to calibrate instruments. For example, in oscilloscopes or multimeters, they can be adjusted to enhance measurement accuracy, ensuring reliable and precise results.

ConclusionTrimmer potentiometers, exemplified by the CFR-50JB-52-1K3, are integral components in modern electronics, providing adjustable resistance for calibration and fine-tuning across a multitude of applications. Their compact design, durability, and low noise operation make them suitable for diverse uses, ranging from consumer electronics to industrial applications. As technology advances, the demand for precise control and calibration will continue to grow, reinforcing the significance of trimmer potentiometers in future electronic developments.

Application Development in Arrays and Signal Transformers for CFR-25JB-52-1R2: Key Technologies and Success StoriesApplication development in arrays and signal transformers, particularly for components like the CFR-25JB-52-1R2, involves a blend of electronic engineering, software development, and system integration. The CFR-25JB-52-1R2 is a precision resistor widely used in various electronic applications, including signal processing and conditioning. Below is an overview of key technologies and success stories related to this area.

Key Technologies1. Array Technology2. Signal Transformers3. Digital Signal Processing (DSP)4. Microcontroller and FPGA Integration5. Simulation and Modeling Tools1. Telecommunications2. Medical Devices3. Consumer Electronics4. Industrial Automation5. Automotive Applications Success Stories ConclusionThe development of applications using arrays and signal transformers, such as the CFR-25JB-52-1R2, is a dynamic field that combines various technologies to create innovative solutions across multiple industries. The success stories highlight the importance of these components in enhancing performance, reliability, and user experience in electronic systems. As technology continues to evolve, the integration of advanced signal processing techniques and smart control systems will likely lead to even more groundbreaking applications, driving further advancements in electronic design and functionality.

CFR-25JB-52-1M2 Adjustable Inductors: Core Functional Technology and Application DevelopmentIntroduction to Adjustable Inductors

Adjustable inductors, such as the CFR-25JB-52-1M2, are critical components in various electronic circuits, enabling the tuning of inductance values to meet specific application requirements. These inductors are particularly valuable in RF (radio frequency) applications, filters, oscillators, and other circuits where precise inductance control is essential. Core Functional Technology1. Variable Inductance Mechanism2. Material Composition3. Temperature Stability4. Compact Design5. High Q Factor1. RF Tuners2. Oscillator Circuits3. Filters4. Power Supply Regulation5. Educational and Prototyping Applications Application Development Cases ConclusionThe CFR-25JB-52-1M2 adjustable inductor represents a versatile and essential component in modern electronics. Its core functional technologies, including variable inductance mechanisms, high Q factor, and temperature stability, make it suitable for a wide range of applications. From RF tuners to power supply regulation, the adjustable inductor plays a crucial role in enhancing circuit performance and enabling innovative designs. As technology continues to evolve, the demand for such adaptable components will only increase, driving further advancements in adjustable inductor technology. The CFR-25JB-52-1M2 stands as a testament to the importance of flexibility and precision in electronic design, paving the way for future innovations.

Application Development in Aluminum-Polymer Capacitors for CFR-25JB-52-1K2: Key Technologies and Success StoriesAluminum-polymer capacitors, such as the CFR-25JB-52-1K2, are increasingly favored in various electronic applications due to their unique characteristics, including high capacitance, low equivalent series resistance (ESR), and excellent thermal stability. Below, we explore the key technologies that underpin their development and highlight notable success stories across different industries.

Key Technologies1. Electrolyte Formulation2. Anode and Cathode Materials3. Manufacturing Techniques4. Thermal Management5. Simulation and Modeling6. Integration with Other Components1. Consumer Electronics2. Automotive Applications3. Renewable Energy Systems4. Industrial Automation5. Telecommunications Success Stories ConclusionThe development and application of aluminum-polymer capacitors like the CFR-25JB-52-1K2 are driven by advancements in materials science, manufacturing techniques, and integration strategies. Their success across diverse industries underscores their versatility and performance advantages, making them essential components in modern electronic systems. As technology continues to evolve, further innovations in aluminum-polymer capacitors are anticipated, paving the way for new applications and enhanced performance in the future.

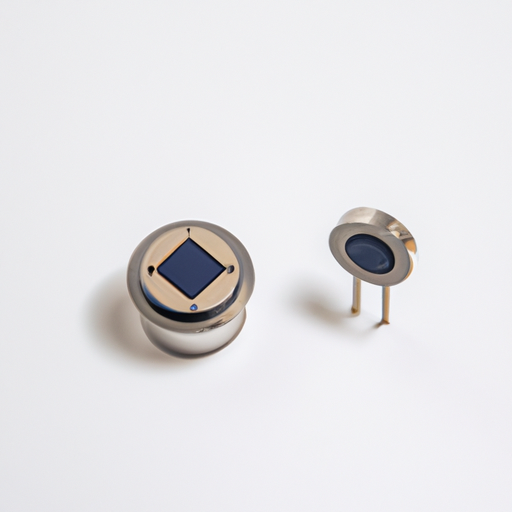

Overview of Silicon Capacitors: CFR-50JB-52-1K2Silicon capacitors, particularly models like the CFR-50JB-52-1K2, are at the forefront of capacitor technology, providing enhanced performance and reliability across a wide range of applications. This document highlights the core functional technologies and application development cases that underscore the effectiveness of silicon capacitors.

Core Functional Technologies1. Silicon-Based Dielectric Material2. Miniaturization3. High Capacitance Density4. Low Leakage Current5. Integration with Integrated Circuits (ICs)6. Enhanced Reliability1. Consumer Electronics2. Automotive Applications3. Telecommunications4. Medical Devices5. Industrial Automation6. Renewable Energy Systems Application Development Cases ConclusionSilicon capacitors, exemplified by the CFR-50JB-52-1K2, represent a significant advancement in capacitor technology, offering numerous advantages in size, performance, and reliability across various applications. Their integration into consumer electronics, automotive systems, telecommunications, medical devices, industrial automation, and renewable energy systems highlights their versatility and effectiveness in meeting the demands of modern technology. As the need for compact, efficient, and reliable electronic components continues to rise, silicon capacitors are set to play an increasingly pivotal role in future innovations.

Core Functional Technologies of Thin Film Capacitors1. Material Composition2. Fabrication Techniques3. High Capacitance Density4. Low Equivalent Series Resistance (ESR)5. Temperature Stability6. Integration with Other Technologies1. RF and Microwave Applications2. Power Electronics3. Consumer Electronics4. Automotive Applications5. Medical Devices6. Aerospace and Defense Application Development Cases ConclusionThin film capacitors represent a significant advancement in capacitor technology, offering high performance, compact size, and versatility across various applications. Their integration with other electronic components, such as the MM74HC393N dual 4-bit binary ripple counter, enhances the functionality of modern electronic systems. As technology continues to evolve, the demand for thin film capacitors in emerging applications will likely grow, driving further innovation in materials and fabrication techniques. The ongoing development in this field promises to unlock new possibilities in electronics, paving the way for more efficient, reliable, and compact devices.

Mica and PTFE Capacitors: Core Functional Technologies and Application Development CasesMica and PTFE (Polytetrafluoroethylene) capacitors are specialized electronic components that leverage their unique properties to serve a variety of applications across different industries. Below, we delve into the core functional technologies, advantages, and notable application development cases for both types of capacitors.

Core Functional Technologies Mica Capacitors

1. **Dielectric Properties**: Mica capacitors utilize natural mica as a dielectric material, which offers exceptional stability, low loss, and high insulation resistance. This stability allows them to maintain capacitance values with minimal drift over time.2. High Voltage Ratings: These capacitors can handle high voltages, making them ideal for applications in power electronics, RF circuits, and other high-voltage environments. 3. Low Temperature Coefficient: Mica exhibits a low temperature coefficient, ensuring that capacitance values remain stable across a wide temperature range, which is crucial for precision applications.

4. Mechanical Stability: Mica capacitors are robust and can withstand mechanical stress, making them suitable for environments subject to vibration or shock.

PTFE Capacitors

1. **Chemical Resistance**: PTFE capacitors are renowned for their excellent chemical resistance, making them suitable for harsh environments where exposure to corrosive substances is a concern.2. Low Loss Factor: PTFE has a very low dissipation factor, allowing for high-frequency applications with minimal energy loss, which is essential in modern electronic designs.

3. Wide Temperature Range: PTFE capacitors can operate effectively over a broad temperature range, typically from -55°C to +200°C, enhancing their versatility across various applications.

4. Low Dielectric Constant: The low dielectric constant of PTFE enables smaller capacitor sizes while maintaining capacitance values, which is advantageous in compact electronic designs.

Application Development Cases Mica Capacitors

1. **RF and Microwave Applications**: Mica capacitors are extensively used in RF amplifiers, oscillators, and filters due to their stability and low loss characteristics. For example, in telecommunications, they are critical in high-frequency circuits where precision is essential.2. Power Electronics: In power supply circuits, mica capacitors are employed in snubber circuits and energy storage applications due to their high voltage ratings and reliability, ensuring efficient operation in power conversion systems.

3. Aerospace and Defense: Mica capacitors are commonly found in military and aerospace applications, where reliability and performance under extreme conditions are paramount. They are used in radar systems, satellite communications, and avionics.

PTFE Capacitors

1. **Medical Devices**: PTFE capacitors are utilized in medical equipment, such as imaging devices and diagnostic tools, where chemical resistance and reliability are crucial for patient safety and accurate diagnostics.2. Automotive Applications: In automotive electronics, PTFE capacitors are employed in systems requiring high reliability and performance, such as electric vehicles and advanced driver-assistance systems (ADAS), where they help maintain signal integrity.

3. Industrial Automation: PTFE capacitors are used in industrial control systems and automation equipment, where they help maintain signal integrity and reduce noise in high-frequency applications, contributing to the efficiency of manufacturing processes.

ConclusionMica and PTFE capacitors each offer distinct advantages that make them suitable for specific applications across various industries. Mica capacitors excel in high-frequency and high-voltage applications, while PTFE capacitors are favored for their chemical resistance and low-loss characteristics. Understanding these properties and their applications enables engineers to select the appropriate capacitor for their designs, ensuring reliability and performance in demanding environments. As technology continues to evolve, the role of these capacitors in advanced electronic systems will likely expand, driving further innovation in their applications.

Application Development in Film Capacitors for CFR-50JB-52-1M1: Key Technologies and Success StoriesFilm capacitors, such as the CFR-50JB-52-1M1, are integral components in a wide range of electronic applications due to their superior electrical characteristics, reliability, and stability. Below, we explore key technologies that have advanced the development of film capacitors and highlight notable success stories across various industries.

Key Technologies1. Material Innovations2. Dielectric Layer Design3. Manufacturing Techniques4. Integration with Power Electronics5. Environmental Considerations1. Renewable Energy Systems2. Electric Vehicles (EVs)3. Consumer Electronics4. Industrial Automation5. Telecommunications Success Stories ConclusionThe application development of film capacitors, such as the CFR-50JB-52-1M1, is propelled by advancements in materials, manufacturing techniques, and integration with modern technologies. The success stories across various industries underscore the versatility and reliability of film capacitors, establishing them as critical components in the development of innovative electronic solutions. As technology continues to evolve, the role of film capacitors is expected to expand, particularly in emerging fields like renewable energy, electric vehicles, and advanced consumer electronics. The ongoing research and development in this area promise to unlock new applications and enhance the performance of electronic systems globally.

Application Development in Ceramic Capacitors for CFR-50JB-52-1K1: Key Technologies and Success StoriesCeramic capacitors, particularly the CFR-50JB-52-1K1, are integral components in modern electronic systems due to their reliability, stability, and performance characteristics. The development and application of these capacitors involve several key technologies and methodologies that enhance their functionality across various industries. Below are insights into these technologies and notable success stories.

Key Technologies1. Material Science Innovations2. Manufacturing Techniques3. Simulation and Modeling4. Testing and Quality Assurance1. Consumer Electronics2. Automotive Applications3. Telecommunications4. Medical Devices5. Industrial Automation Success Stories ConclusionThe application development of ceramic capacitors like the CFR-50JB-52-1K1 is propelled by advancements in materials, manufacturing processes, and testing methodologies. Their versatility and reliability have led to successful implementations across diverse industries, including consumer electronics, automotive, telecommunications, medical devices, and industrial automation. As technology continues to evolve, the role of ceramic capacitors is expected to expand, paving the way for new applications and innovations that will further enhance electronic systems.

Application Development in Aluminum Electrolytic Capacitors for CFR-50JB-52-1R1: Key Technologies and Success StoriesAluminum electrolytic capacitors, such as the CFR-50JB-52-1R1, are integral components in a wide range of electronic applications due to their high capacitance values, cost-effectiveness, and reliability. The development and application of these capacitors involve several key technologies and methodologies that enhance their performance and longevity. Below are some of the key technologies and notable success stories associated with aluminum electrolytic capacitors.

Key Technologies1. Electrolyte Formulation2. Anodization Techniques3. Improved Foil Manufacturing4. Hybrid Capacitor Technologies5. Simulation and Modeling6. Environmental Considerations1. Consumer Electronics2. Automotive Applications3. Renewable Energy Systems4. Industrial Automation5. Telecommunications Success Stories ConclusionThe application development of aluminum electrolytic capacitors, such as the CFR-50JB-52-1R1, is propelled by advancements in materials, manufacturing processes, and design methodologies. These innovations have led to significant improvements in performance, reliability, and environmental sustainability, making aluminum electrolytic capacitors a preferred choice in various high-demand applications. As technology continues to evolve, we can anticipate further enhancements and new success stories in this dynamic field, reinforcing the importance of aluminum electrolytic capacitors in modern electronics.

Application Development in Specialized Resistors for CFR-25JB-52-1R: Key Technologies and Success StoriesThe CFR-25JB-52-1R is a precision resistor from the CFR series, renowned for its reliability and accuracy across a variety of applications. This document explores the key technologies that underpin its development and highlights notable success stories that demonstrate its impact across different industries.

Key Technologies1. Thin Film Technology 2. Automated Manufacturing Processes 3. Material Science Innovations 4. Custom Resistance Values 5. Environmental Compliance 6. Simulation and Modeling 1. Medical Devices 2. Automotive Applications 3. Telecommunications 4. Consumer Electronics 5. Industrial Automation Success Stories ConclusionThe CFR-25JB-52-1R resistor exemplifies the advancements in resistor technology and its applications across various industries. By leveraging innovations in materials, manufacturing processes, and design, these specialized resistors continue to play a crucial role in the development of reliable and efficient electronic systems. The success stories across medical, automotive, telecommunications, consumer electronics, and industrial automation highlight the versatility and importance of such components in modern technology. As industries evolve, the demand for high-performance resistors like the CFR-25JB-52-1R will only continue to grow, driving further innovation and application development.

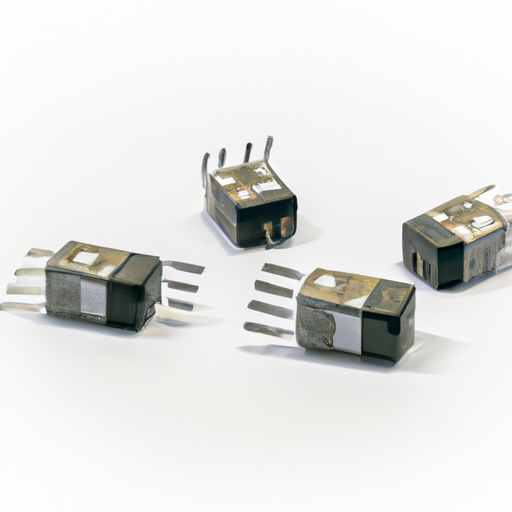

Application Development in Through-Hole Resistors for CFR-50JB-52-1M: Key Technologies and Success StoriesThrough-hole resistors, such as the CFR-50JB-52-1M, are integral components in electronic circuits, valued for their reliability, stability, and ease of handling during assembly. This overview highlights the key technologies that underpin their development and some notable success stories across various applications.

Key Technologies1. Material Science2. Manufacturing Techniques3. Design Innovations4. Thermal Management5. Circuit Design Integration1. Consumer Electronics2. Industrial Applications3. Medical Devices4. Automotive Electronics5. Educational Projects Success Stories ConclusionThrough-hole resistors like the CFR-50JB-52-1M are essential components across various industries, offering reliability, ease of use, and excellent performance characteristics. As technology continues to advance, the integration of these resistors into new applications is expected to grow, driven by ongoing innovations in materials and manufacturing processes. Their role in critical applications—from consumer electronics to medical devices—demonstrates their enduring value in the electronics landscape.

Application Development in RF and Wireless for CFR-25JB-52-1K: Key Technologies and Success StoriesApplication development in RF (Radio Frequency) and wireless technologies, particularly in the context of CFR-25JB-52-1K, encompasses a variety of key technologies and methodologies that facilitate effective communication and data transfer across numerous applications. CFR-25JB-52-1K may refer to a specific standard or component in RF systems, and while the exact context is not provided, the following overview highlights essential technologies and notable success stories in RF and wireless application development.

Key Technologies in RF and Wireless Development1. Modulation Techniques2. Antenna Design3. RF Components4. Software-Defined Radio (SDR)5. Network Protocols6. Signal Processing7. IoT Integration1. Smart Agriculture2. Healthcare Monitoring3. Smart Cities4. Industrial Automation5. Telecommunications6. Consumer Electronics Success Stories in RF and Wireless Application Development ConclusionThe development of RF and wireless applications, particularly in the context of standards like CFR-25JB-52-1K, is propelled by advancements in modulation techniques, antenna design, and IoT integration. The success stories across various sectors illustrate the transformative impact of these technologies, leading to improved efficiency, enhanced user experiences, and innovative solutions to contemporary challenges. As the field continues to evolve, ongoing research and development will likely yield even more groundbreaking applications and technologies, further shaping the future of RF and wireless communication.